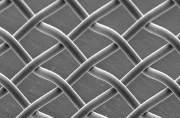

In this range of products, the usage of stainless steel wires of much higher strength than BS and low elongation, results in woven meshes with a larger percentage of open area. In the range of 60%, the meshes are suitablle to facilitate the transfer of thicker pastes. Applications like Photovoltaic Cell Metallization by screen printing make extensive use of this type of fabrics.

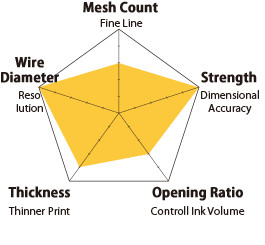

Product Range