for high quality screen printing

Our Products for Screen Printing are categorized as Standard, Hardmesh, Supermesh, 3D-mesh and Ultra-Hard mesh. They have their own mesh count, wire diameter, thickness, strength so that it can be selected depending on customers’ needs or printing applications.

AD-Screen series

For Screen Printing Applications

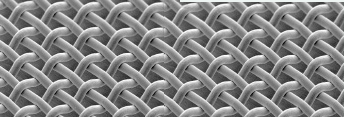

Ultra Hard

The tensile strength of HS-D meshes is 3 times greater than BS-Standard. Produces more stable and dimensional accurate print. Screen printing potential will be further enhanced.

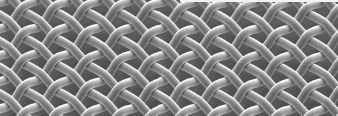

Super Mesh

Using stainless wires of high strength and low elongation, these meshes are woven with an open ratio of 60%. Thus, the transmittance of printing paste improves

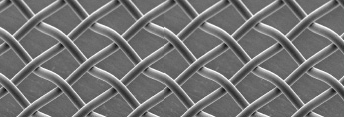

Hard Mesh

The tensile strength of these meshes has been improved to 30% greater than BS Standard. Higher printed resolution has been achieved through the development of 640 and 730 mesh

Standard

As a standard mesh for screen printing, it’s has been adopted for wide use such as fine line or thin deposit printing for MLCC

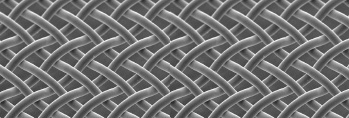

3D Mesh

The wires are woven into a special weaving structure which yields a mesh 3 times thicker than the wire diameter; which is suitable for Thick Deposit printing

Valued Added Process for Woven Wire Cloth

CALENDER - Type CL

Woven wires are roll-calendering to be as thin as single wire diameter. Thickness uniformity will be further enhanced through this process.

BLACK SCREEN - Type BLK

Woven wires are blackened through surface treatment. It enhances printing resolution by preventing random light reflection during the UV exposure process.

Asada Mesh keeps commited to develop newer materials to fill the needs of you loyal Customers.

Stainlesss Steel Wire Mesh is necessary to print finer and more accurate printing images. “We Will continue to develop finer and stronger metal meshes to help advance Screen Printing Technology”